Ceramic metal welding process

Ceramics in the welding of ceramics and metals basically refer to new types of ceramics artificially synthesized by various metals, oxygen, nitrogen, carbon, etc. It has the characteristics of high strength, high temperature resistance, abrasion resistance, corrosion resistance, super hardness, etc., and is widely used; commonly used alumina, silicon nitride, zirconia ceramics, etc.

Portable Laser Welding Machine Supplier

Difficulties in welding ceramics and metals

1. The linear expansion coefficient of ceramics is small, while the linear expansion coefficient of metal is relatively large, which leads to easy cracking. Generally, the thermal stress of the metal intermediate layer should be handled well.

2. The ceramic itself has low thermal conductivity and weak thermal shock resistance. When welding, minimize the temperature gradient of the welding part and the surrounding area, and control the cooling rate after welding.

3. Most ceramics have poor conductivity, or even non-conductivity, which makes it difficult to use electric welding. To this end, special process measures are required.

4. Due to the stable electronic coordination of ceramic materials, the connection between metal and ceramic is unlikely. Need to metallize ceramics or braze with active solder.

China Handheld Welding Manufacture

5. Since ceramic materials are mostly covalent crystals, they are not easily deformed and brittle fractures often occur. At present, the intermediate layer is mostly used to reduce the welding temperature, and the indirect diffusion method is used for welding.

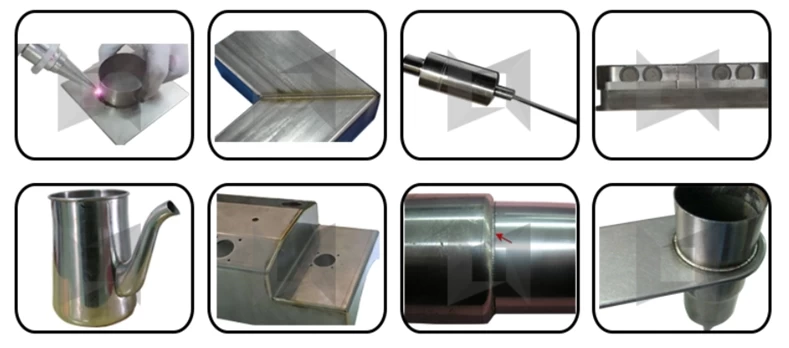

6. The structural design of ceramic and metal welding is different from ordinary welding. It is usually divided into flat seal structure, sleeve structure, pin seal structure and double seal structure. The sleeve structure has the best effect. The production requirements of these joint structures are all Very high.

The general process of ceramic and metal welding

1. Cleaning: The surface of metal and brazing filler metal must be cleaned. Ceramics are usually cleaned with detergent and ultrasonic.

2. Paste: Most pastes are composed of pure metal powders and appropriate metal oxide powders. The particle size is mostly between 1 and 5um. The pastes are prepared with organic binders to have a certain viscosity. Then use a paint tool to evenly spread the paste on the ceramic surface to be metallized, and the thickness of the coating is generally 30-60um.

3. Metallization: Put the paste-coated pseudo-ceramic parts into a hydrogen furnace and keep them at a temperature of 1300~1500℃ for 1h.

4. Nickel plating: For better solder wetting, a nickel layer with a thickness of about 5um is plated on the metallization layer. When the brazing temperature is lower than 1000°C, the electroplating layer needs to be pre-sintered in a hydrogen furnace at 1000°C for 15-20 minutes.

5. Mounting: Assemble the processed metal parts and ceramic parts into a whole with stainless steel, graphite, and ceramic molds, and install brazing parts at the joints; the parts to be welded should be kept clean during the entire operation, and no bare Hand touch.

6. Brazing: brazing is carried out in a furnace with argon gas or a furnace with hydrogen gas or a vacuum furnace. The temperature selection and heating rate selection should be determined according to the characteristics of the solder used, and special attention should be paid to The cooling rate should not be too fast to prevent the ceramic parts from cracking due to temperature stress.

7. Post-weld inspection: After the ceramic and metal are welded, firstly observe the qualification by naked eyes, and then perform the necessary inspections according to the requirements of the technical documents.