Eleven items for safe use of hand-held laser welding machines

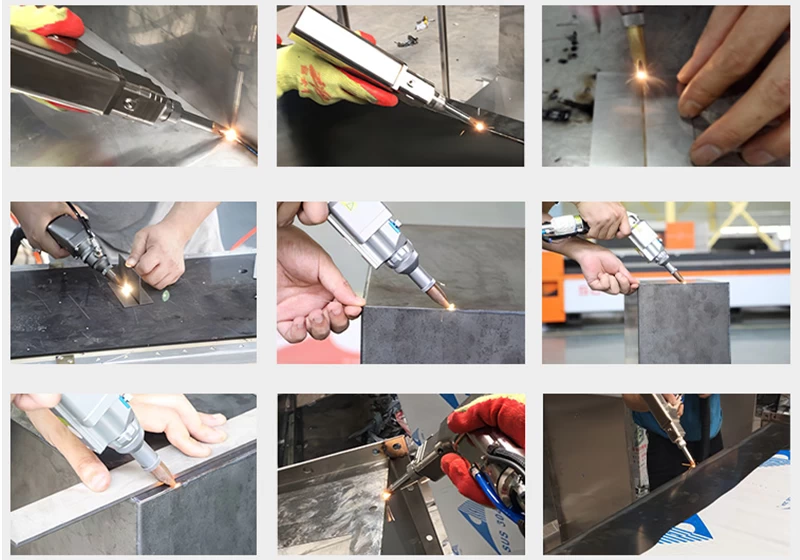

With the development of technology and the decline of cost, laser welding is expanding into new "sinking markets" - aluminum alloy doors and windows, stainless steel pipes, metal fences, bathroom accessories, custom furniture, handicrafts, chassis, water tanks, cabinets, cabinets, The welding of stainless steel guardrails and other products is often irregular and can be carried out without fixtures. Hand-held laser welding is a powerful tool to open up this new market.

China Handheld Welding Manufacturer

The excellent welding quality, flexible welding method and easy-to-use advantages of handheld laser welding have made it popular in many application scenarios that require traditional argon arc welding, winning the recognition and favor of users. So what safety precautions should I pay attention to when using a handheld laser welding machine?

1. Equip relevant responsible personnel. Responsible personnel must have relevant knowledge and experience of laser and hand-held laser welding machines. The person in charge should not only be in charge of the safety lock key and password of the handheld laser welding machine, but also instruct the operator how to use the handheld laser welding machine and teach relevant safety knowledge.

2. Establish a dedicated laser welding area. The relevant person in charge is responsible for establishing a dedicated laser welding area (separated from other working areas by protective fences and other similar devices), and at the same time, relevant signs such as "prohibition of access by idle personnel" should be set up in the welding area.

3. Place the hand-held laser welding machine in a level and firm place, and do not place it in an inclined place. The handheld laser welding machine uses AC three-phase 380V/100A (50~60Hz) mains power.

4. Please use this handheld laser welding machine in an environment where the ambient temperature is 5°C-30°C and the humidity is not greater than 85%. The ambient temperature should not fluctuate too much. It is forbidden to use this handheld laser welding machine in the following environments: ① Environment with dust and oil. ②There is a vibration environment. ③ Corrosive environment. ④ high-frequency noise environment. ⑤ In a humid environment. In environments with high concentrations of carbon, nitrogen and sulfur oxides (CO2, NOx or SOx) in the air.

5. In winter, if the ambient temperature drops below 0°C, the water in the chiller and/or the water tank will freeze, and the water tank may freeze. So take special care to ensure that the ambient temperature of the handheld laser welding machine is not lower than 0°C in winter.

6. If the ambient temperature changes drastically, water vapor will form on the laser rod and lens, which will affect the use of the handheld laser welding machine. Therefore, drastic changes in ambient temperature should be prevented as much as possible. If water vapor has been formed, it must be preheated for a period of time after turning on the machine before using the machine.

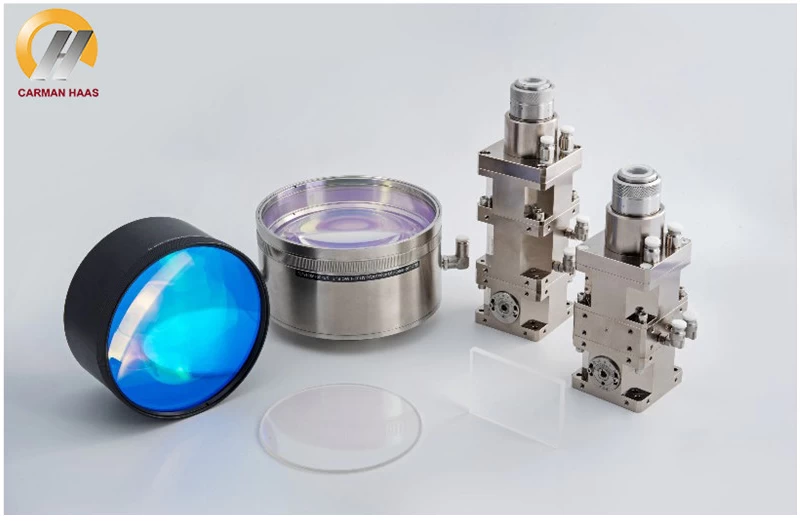

Galvo Head Laser Welding Manufacturer

7. If the case of the handheld laser welding machine has stains or water, please wipe it dry with a dry or damp cloth. If the stain cannot be wiped clean, it can be wiped off with a neutral detergent or alcohol. Do not wipe the machine with gasoline or paint thinner.

8. It is forbidden to put screws or coins inside or outside the hand-held laser welding machine, which may cause a short circuit and damage the machine.

9. Please operate the button gently by hand, do not touch the button with tools such as a screwdriver. In particular, do not touch the touch screen with sharp objects, which will cause permanent damage to the touch screen (operate the touch screen with fingers or a special touch pen).

10. Do not operate the buttons and switches continuously, and ensure that they are only pressed once at a time. Repeated switching has an impact on the life of the machine.

11. The control box and the hand-held laser welding machine are connected by connecting wires. After removal, make sure all connections are restored before next use. At the same time, do not let the cable block the optical fiber.