Focusing of laser marking

Laser marking machine is the product of technological development and progress, and is widely used in product packaging and coding. The laser marking machine mainly uses the focusing system to focus the laser on the surface of the object for marking. However, because of the different thickness and height of the processed workpiece during work, we often need to adjust the height of the lens and adjust the focal length, so how do we adjust the focus? , To find the right focal length?

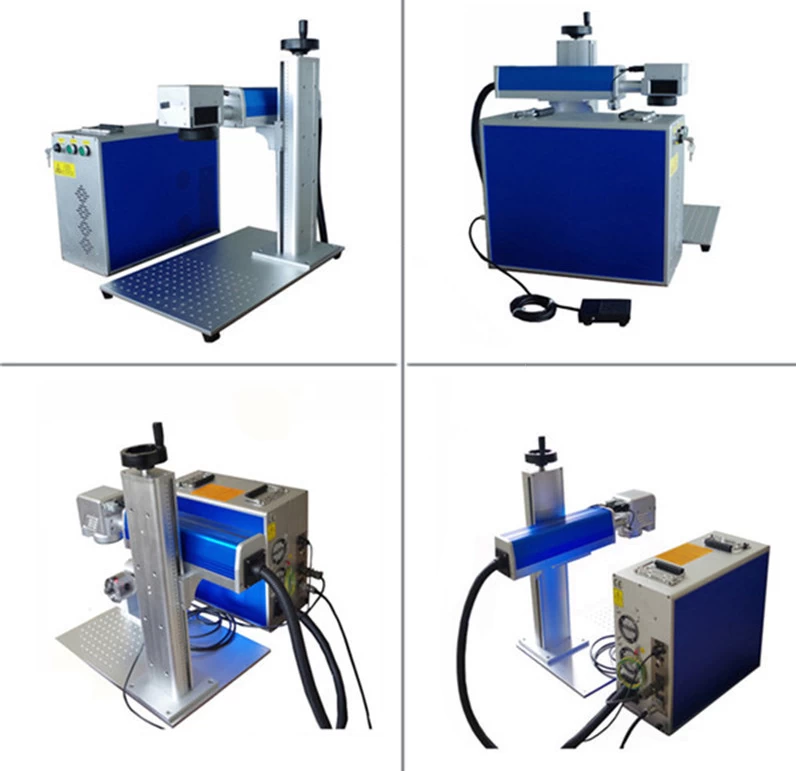

green laser marking machine in china

If the focal length of the laser is too high or too low, the correct focal length will be missed. Introduce three conventional methods to find the focal length:

The first type: continuous luminescence test method.

After the marking paint software is about one centimeter square or circular, after regular filling, the laser energy is transferred to the set parameter column, the frequency of use, and then the continuous marking is checked, and a metal laser projection position card obstacle is placed on the surface of the product, such as Continuous cursor, shaking the Z-axis action, only on the correct focal length plane, the laser spot is the smallest, the energy is the strongest, and the sound and color are the brightest after the laser reaches the object, which is basically the appropriate focal length.

1064nm focus lens on sale supplier

The method is suitable for 1064nm wavelength fiber laser marking machine, semiconductor laser marking machine, end pump laser marking machine, 355nm laser marking machine, uv 532nm green laser marking machine, etc. You can find one for carbon dioxide laser marking machine White paper, and then draw a box in the marking software, continuous light shakes the Z axis, and the focal plane is the finest when the paper is printed on the line.

The second method: measure the focal length.

After the device manufacturer notifies the current device focal length data, it can be recorded, and then after each product switch. You can align the end of the ruler directly on the surface of the product. The scale value refers to a certain reference surface on the field lens, which is jittered up and down to scale the data. This method is suitable for all laser marking machines, but the disadvantage is that if the position of the laser engraved product is concave or the steel ruler is inappropriate, this method is not practical.

532nm Telecentric Lenses on Sale China

Third: Double red light value method.

This method requires the device to have this hardware configuration at the factory. Install one or two oblique red rays next to the galvanometer or galvanometer, and use the principle of a right triangle to find the other right side of the focal plane by using a fixed right side and two overlapping hypotenuses. You can quickly find the focal length by simply shaking it up and down until the two red indicators coincide. Although this method is convenient and quick, it requires the equipment manufacturer to cooperate with the secondary equipment. In addition, if the adjustment is not good or the intermediate shift is carried out, it is easy to mislead and form the wrong focus surface