Photovoltaic laser non-destructive cutting

In the photovoltaic industry, the most important aspect of photovoltaic production is battery manufacturing. Silicon cells play an important role in photovoltaic power generation, whether it is a crystalline silicon cell or a thin-film silicon cell. In crystalline silicon cells, high-purity single crystals/polycrystals are cut into silicon wafers for the battery, and lasers are used to accurately cut, shape, and scribe, make the battery and then string together.

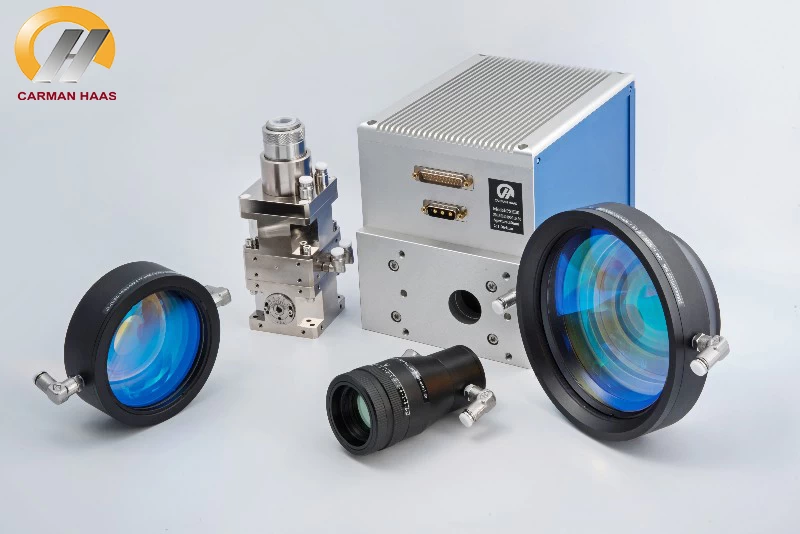

(Optical System For Laser Processing Onsolar Cell) Non-destructive cutting of photovoltaic cells, providing half-cell modules, three-cell modules, sheet modules, board interconnect components, and seamless welding of main components of multi-bus grids. Laser nondestructive cutting has become an indispensable process for the iterative upgrade of component products.

The core principle of the non-destructive laser cutting technology is the laser thermal stress control fracture technology: the laser is used to quickly heat the material locally, followed by the supporting cooling technology to produce an uneven temperature field, which will generate a temperature gradient on the surface of the material , Thereby inducing the generation of thermal stress; the laser spot is in a state of compressive stress, and the laser spot is in a state of tensile stress before and after the laser spot; because the compressive stiffness of brittle materials is much greater than the tensile strength, when the tensile stress reaches the breaking strength of the material, it will The material is broken, and the fracture will steadily expand with the moving track of the laser and subsequent cooling. The premise is that an ultra-small notch is machined on the edge of the cell, and the fracture expansion will start from the notch. The components obtained by non-destructive laser cutting have no scratches on the surface, no dust pollution, no slag tumors, and small burrs.

(Optical System Laser Processing Onsolar Cell) CARMANHAAS provides different photovoltaic optical laser system solutions.Cutting technology can realize the non-destructive cutting of photovoltaic cells and improve the damage of the cut surface.