SLM metal 3D printing technology: problems and solutions involved in laser scanning

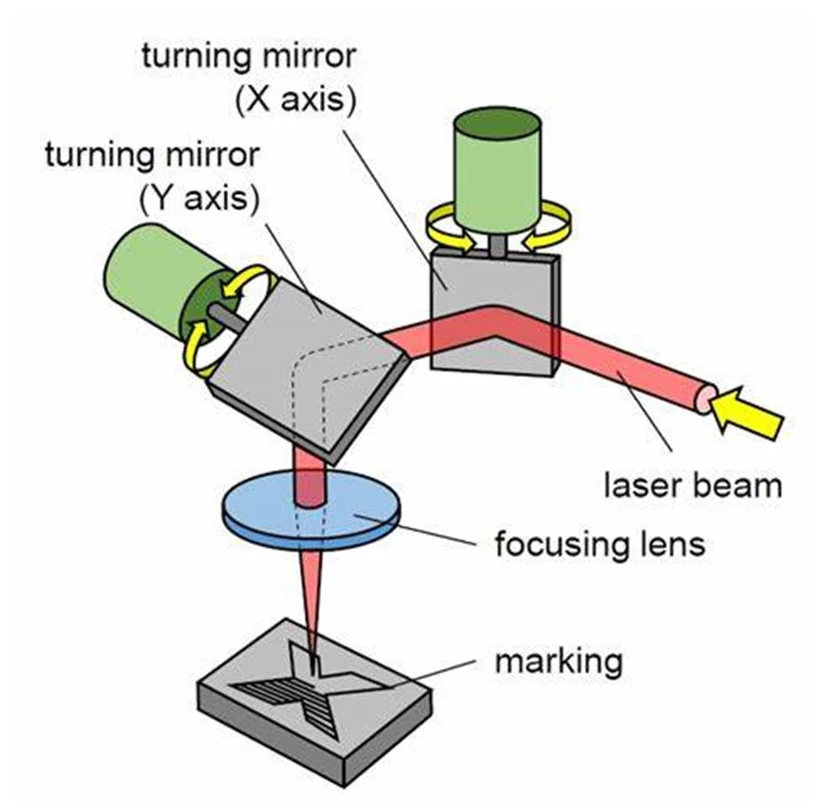

Among various types of laser scanning technologies, galvanometer laser scanning is a widely used laser scanning method. It has the advantages of high speed, high precision, stable performance, etc., but it has the problem of focusing error that the focus of the spot is not on the processing surface. In addition, galvanometer laser scanning has linear distortion and non-linear distortion of scanning graphics, especially when the scanning area is large, it seriously affects the graphics accuracy and processing quality of laser scanning.

Pincushion distortion-the solution:

Since the generated distortion is not the same in the X and Y directions, it cannot be corrected by the method of conventional lenses. The method of distortion formula software can be used to correct the address mapping relationship between the ideal map and the distortion map. The plane coordinate transformation method can solve this problem well.

Focus error

Before introducing the solution, we first introduce an important concept: the focal plane. This means that during the focusing process, the laser will form a funnel-shaped light path. This cross section is the focal plane, which is the diameter of the spot.

In high-precision scanning occasions, in order to obtain better scanning results, it is necessary to control the spot radius of the working table within a certain range (the range varies with different scanning equipment). At any position within the scanning range, the laser beam is required to be well focused.

Then in the galvanometer scanning system, this more typical error comes from the focal plane. After the laser passes through the XY oscillator, the focal plane is a spherical plane.

Reflector mirror factory china

Solution

So how can we get a smooth and uniform spot on the forming platform? There are two widely used solutions.

This method is only suitable for laser scanning processing on a smaller work surface.

When scanning, the F-theta lens has a large size and high cost, and the closer to the edge, the worse the compensation effect.

2. Better 3D dynamic focusing technology(F-Theta Scan lenses factory china)

The dynamic focus galvanometer laser scanning system is generally controlled by the upper application software and the lower driving software. Due to the open loop control, three-axis synchronization is required during the movement.

The servo motor driving the galvanometer is driven by analog voltage. The optical model of the dynamic focus scanning system is designed according to the principle of optical lever. The laser beam reaches the scanning field through the dynamic focus system and then twice mirror reflection. Driven by the servo motor, the dynamic focus mirror makes a reciprocating linear motion in the direction of the optical path to compensate the focus error in real time, so as to ensure that the scanning field and working field errors of the spot focus are compensated.

Dynamic focus technology is a laser scanning focus error compensation technology that has emerged in recent years. It has a more effective and precise compensation effect, and it supports a larger field of view and is relatively more expensive.

The SLM equipment uses a three-dimensional dynamic focusing system, which can achieve precise laser control and greatly improve print quality