The use of laser cleaning machine

Laser cleaning is currently a new application technology in the field of laser application technology that is closest to the international frontier,In the field of industrial applications, with the rapid development of lasers and the continuous in-depth study of laser cleaning mechanisms, surface quality monitoring and characterization methods have become more complete and comprehensive. The surface quality of laser cleaning materials has been improved, and the cleaning accuracy and efficiency have gradually increased. It has become a reliable technology that can clean the surface of a large number of different substrates. The cleaning objects include steel, aluminum alloy, titanium alloy, glass and composite materials, etc. The application industries cover aerospace, aviation, shipbuilding, high-speed rail, automobiles, molds, nuclear power, and oceans field.

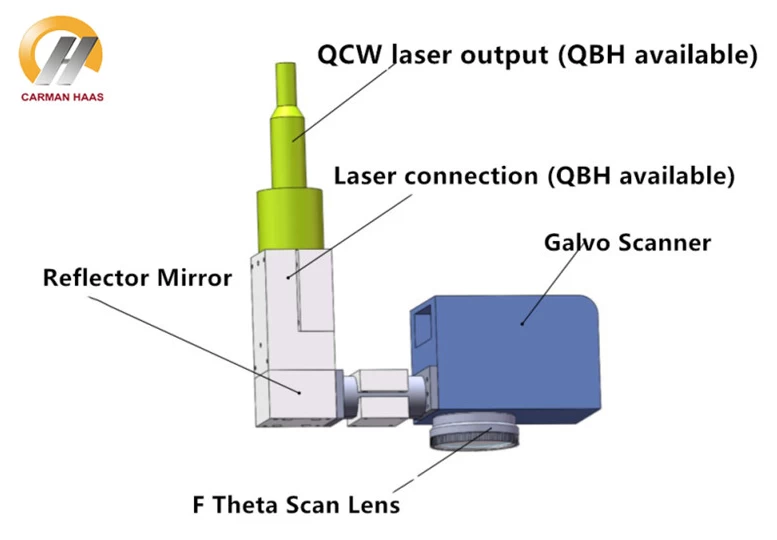

Carmanhaas could offer complete laser cleaning optical lens and system solution. Including QBH Module, Galvo Scanner, F-theta Scan lenses and Control System.

China customized Galvo Laser Head Suppliers

Galvo Scanner for Industrial Laser Cleaning Systems 1000W

Our Galvo Scanner standard model is PSH10, PSH14, PSH20 and PSH30.

Key Advantages:

1.Extremely low temperature drift (≤3urad/℃); Over 8 hours Long-Term Offset Drift ≤30 urad

2.Extremely high resolution and repeatability; resolution≤1 urad; repeatability≤ 2 urad

3.Super high speed:

PSH10: 17m/s

PSH14: 15m/s

PSH20: 12m/s

PSH30: 9m/s

Optics lens for laser cleaning gun manufacturers

Industrial Laser Cleaning Systems for rust removal, paint removal and surface preparation

Advantage:

1.No abrasive materials are used, with no problems of contaminant separation and disposal;

2.No solvents are used - chemical-free and environmentally friendly process;

3.Spatially selective – cleaning only the area required, saving time and costs by ignoring regions that don’t matter;

4.Non-contact process never degrades in quality;

5.Easily automated process that can lower operating costs by eliminating labor while giving greater consistency in results.