Why do the Galvanometer lens often break?

In laser marking machines or galvanometer welding machines, sometimes the galvanometer lens is frequently broken. If you change a galvanometer lens, it still breaks, but the viewing lens is not damaged.

Galvo head laser welding manufacturer

Reason:

1. The galvanometer lens is not coated, so it is easy to break.

2. It is caused by the back reflection point of the field lens just on the galvanometer lens.

What is the back reflection point?

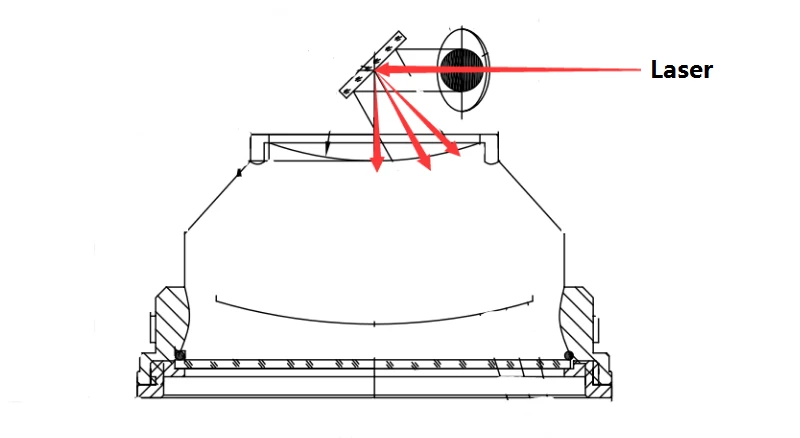

Everyone knows the last lens of the field lens, the side facing the galvanometer lens is a concave mirror. We default that the laser is 100% through the field lens, so the galvanometer lens and the field lens will not affect each other (of course, the position of the galvanometer lens M1 and M2, this must be correct, and there should be no scratches on the field lens), However, the 100% laser transmittance that we said is theoretical. In practice, it is often between 98% and 99.5%, that is, 0.5%-2% of the laser light will be reflected back. According to optical knowledge, we know that a beam Parallel light hits a concave surface and is reflected back to focus on the focal point of the concave surface.

China galvo scan laser processing

The back reflection point drawn in the above picture is the focal point of this concave surface. When the laser is reflected from the concave surface to the back reflection point, if the galvanometer lens happens to be at this position, it means that the laser is focused on the galvanometer lens, so the film of the galvanometer lens is easily damaged.

The solution to this problem is very simple, which is to increase the height of the field lens adapter ring between the galvanometer and the field lens by 3mm, or add a washer to prevent all of them from being screwed in, so that the field lens is farther away from the M2 lens. At this time, when it is reflected back, it will not focus on the M2 lens, and it will not be broken.

customized galvo laser head manufacturer

In our practice, because our optical fiber marking machines are all 20 watts and 30 watts, the light reflected from the last lens of the field lens is about 0.2-0.3 watts, and the reflected light may not necessarily be It is really focused on the vibrating lens, so there is no harm to the vibrating lens, and in most cases, there is no frequent damage to the vibrating lens. However, as continuous lasers of 2000-6000 watts are used for welding, pulsed lasers of 200-300 watts are used for laser cleaning, and picosecond and femtosecond lasers are widely used, this phenomenon of lens damage will become more frequent. So we have to pay attention to this problem. When the vibrating lens is frequently broken, we must think about adding a washer or making a new conversion ring.