What is the difference between laser cutting-vaporization cutting and melting cutting?

Laser cutting uses a high-power density laser beam to irradiate the material to be cut, so that the material is quickly heated to vaporization temperature, and evaporates to form holes. As the beam moves on the material, the holes continuously form a narrow width (such as about 0.1 mm). Cut the seam to complete the cutting of the material.

Laser cutting can be divided into four categories: laser vaporization cutting, laser melting cutting, laser oxygen cutting and laser scribing and controlled fracture. Today I will talk to you about vaporized cutting and melting cutting.

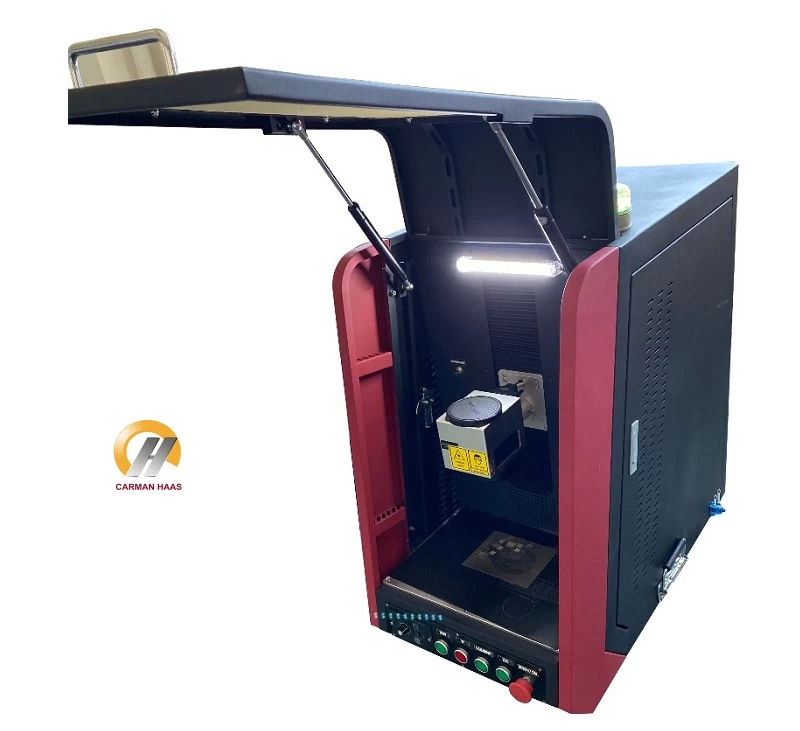

Laser Cutter,Engraver & Marking Machines factory

Analysis of the difference between vaporization cutting and melting cutting of laser cutting:

Laser vaporization cutting is to use a high-energy density laser beam to heat the workpiece, so that the temperature rises rapidly, reaching the boiling point of the material in a very short time, and the material begins to vaporize to form vapor. The jetting speed of these vapors is very high, and at the same time as the vapor jets, cuts are formed in the material. The heat of vaporization of materials is generally very large, so a large power and power density are required for laser vaporization and cutting.

Laser vaporization cutting is mostly used for cutting extremely thin metal materials and non-metal materials (such as paper, cloth, wood, plastic, rubber, etc.).

In laser melting and cutting, the metal material is melted by laser heating, and then non-oxidizing gas (Ar, He, N, etc.) is sprayed through a nozzle coaxial with the beam, and the liquid metal is discharged by the strong pressure of the gas to form an incision. Laser melting and cutting do not need to vaporize the metal completely, and the energy required is only 1/10 of that of vaporized cutting.

Laser melting cutting is mainly used for cutting some materials that are not easy to oxidize or active metals, such as stainless steel, titanium, aluminum and their alloys.

China Laser Cutting Machine Manufacturer

Because of the small laser spot, high energy density, and fast cutting speed, laser cutting can obtain better cutting quality. The laser cutting incision is narrow, the two sides of the incision are parallel and perpendicular to the surface, and the dimensional accuracy of the cut parts can reach ±0.05mm. The cutting surface is smooth and beautiful, and the surface roughness is only tens of microns. Even laser cutting can be used as the last process without mechanical processing, and the parts can be used directly. After the material is laser cut, the width of the heat-affected zone is very small, and the performance of the material near the slit is almost unaffected, and the deformation of the workpiece is small, the cutting accuracy is high, the geometric shape of the slit is good, and the cross-sectional shape of the slit is relatively regular. rectangle.

The laser cutting speed is fast; there is no contact between the torch and the workpiece during laser cutting, and there is no tool wear. Processing parts of different shapes does not need to change the "tool", just change the output parameters of the laser and adjust the optical path. The laser cutting process has low noise, low vibration and no pollution.

CARMANHAAS is china professional manufacturer in laser optics and optical system manufacturer to offer Laser Cutter, laser welding machine,laser marking machine, laser engraving machines,etc Cutting Machine Parts Supplier to be leader supplier in china with best price. all our products are good quality with CE ISO certificated.Welcome to browse carmanhaas company website for more information of laser optics and optical system.