Precautions for the use of laser cutting heads

The laser cutting head of the metal laser cutting machine is its core component. Pay special attention during use. If the damage and repair due to improper operation are very troublesome, the following editor will introduce you to the use of the laser cutting head of the metal laser cutting machine. Matters, I hope it can be helpful to you.

1. Pollution of the fiber end

When plugging and unplugging the optical fiber, operate in a clean space and keep the fiber end and the inside of the fiber interface clean. The lens contaminants inside the cutting head all come from the optical fiber part. Plugging and unplugging the optical fiber in a poorly clean environment will greatly increase the chance of contaminating the inside of the cutting head.

Raytool head cutting lens factory

2. Incorrect operation of plugging and unplugging the optical fiber causes the PIN pin to wear out

The internal PIN needle of the QBH optical fiber interface of the cutting head produces metal shavings after being subjected to external stress during incorrect insertion and removal. During the operation, during the final knob interface, do not use excessive torque. Only the thumb and index finger are required to complete the operation. Excessive force may cause damage to the PIN needle.

3. Keep the outside of the cutting head clean

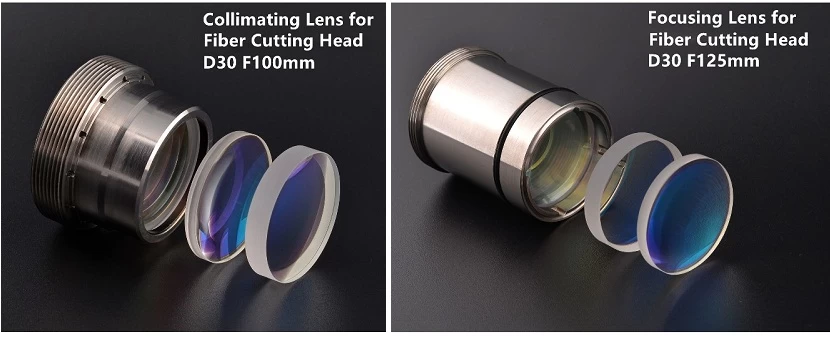

The abrasion of the convex part and the structure and shape of the concave part will cause the accumulation of pollutants. In this case, when the protective lens of the collimator lens is opened, the optical lens will be directly exposed to the threat of the pollution source, which will further cause pollution. Contaminate the collimator lens and focusing lens, causing greater loss, and keep the appearance of the cutting head clean.

4. Do not continue to use the protective lens when there are burning spots

In the case of burning spots on the protective lens, the lens needs to be replaced immediately. After the coating is damaged, it will deflect the laser light. If it is scattered to the inner wall of the cutting head cavity, the temperature will rise, which will also affect the surface of other lenses and cause greater losses.

Focusing lens for fiber cutting head

5. Ensure the cleanliness of the cutting gas

Before using the cutting gas, it is necessary to check the cleanliness of the gas and the gas pipeline, such as residues, water vapor, oil and other contaminants. If the gas has the above impurities, it will increase the risk of contamination of the protective mirror, and thus the frequency of replacing the protective mirror will increase, which will seriously block the gas path and reduce the cutting effect.

6. When the sealing ring is defective, it needs to be replaced in time

When checking the use of the protective mirror, it is also necessary to check the wear of the sealing ring. When the cutting head is working well, the sealing ring should be checked every three days. If you find dirt, please use absolute ethanol to clean it up. If any damage is found, it should be replaced with new accessories. A damaged seal ring will cause a decrease in the sealing function and increase the risk of internal contamination of the cutting head. When replacing the sealing ring of the ProCutter protective mirror, you need to use a coolant to cool the sealing ring before putting the sealing ring into the protective mirror drawer. If no coolant is used, direct installation will result in damage and deformation of the sealing ring, which will directly affect the sealing performance of the sealing ring, and its function will be greatly reduced.

7. Do not use sealant or raw tape to connect the air path of the cutting head

Do not use sealant or raw tape when connecting the cutting head to the air interface. If the residue of the above two items enters the air path, it will directly block the air path and cause the cutting head to fail to operate normally.