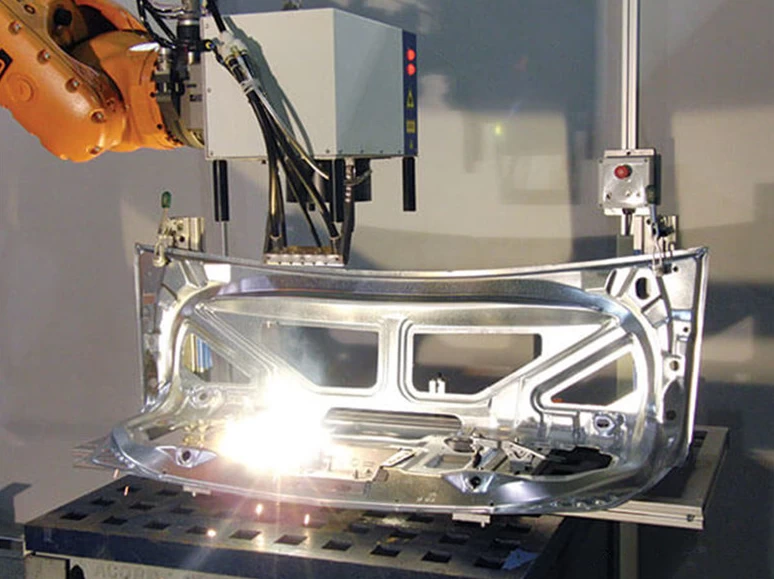

Application of laser welding machine in mold industry

Application of laser welding in the mold industry

The mold laser welding machine is specially designed for the mold industry and used for the repair of precision molds, such as digital products, mobile phones, toys, automobiles, motorcycles and other mold manufacturing and molding industries. Through the repair of the mold, the original mold can be fully used again, which greatly saves production costs and improves work efficiency. This technology can also be applied to modify the design or size of the mold to shorten the product development cycle.

Handheld Welding supplier China

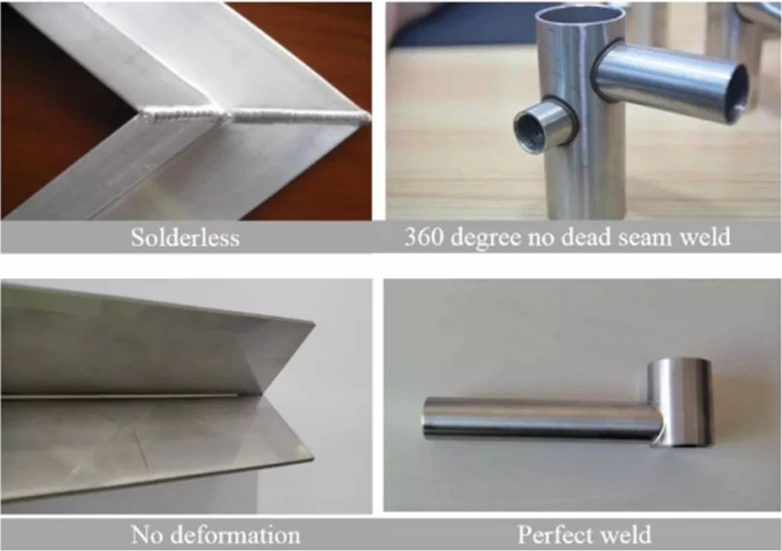

Laser welding machine is a new type of welding method, mainly for welding thin-walled materials and precision parts. It can realize spot welding, butt welding, overlap welding, sealing welding, etc., with high aspect ratio, small weld width, and heat affected zone. Small, small deformation, fast welding speed, smooth and beautiful welding seam, no need to handle or simple processing after welding, high welding seam quality, no air holes, precise control, small focus spot, high positioning accuracy, easy to realize automation.

A typical example of the application of laser welding in the mold industry is the mold repair laser welding machine. This equipment is easy for operators to use, can greatly increase the speed of welding repair, and the repair effect and precision are close to perfect, which makes the equipment It is widely used in the field of mold welding. The repair welding heat-affected area of this welding machine is very small, and it does not need to be heated in advance, and the welded workpiece will not appear annealing after work. This laser welding repair technology can not only be used to repair mold wear, but also can achieve precise welding of small and precise areas, and there will be no deformation or pores after repair.

Galvo scan head welding supplier China

Repair method of mold laser welding:

1. Argon arc welding repair uses the arc burning between the continuously fed welding wire and the workpiece as the heat source, and the gas shielded arc sprayed from the torch nozzle is used for welding. At present, argon arc welding is a commonly used method and can be applied to most major metals, including carbon steel and alloy steel. MIG welding is suitable for stainless steel, aluminum, magnesium, copper, titanium, zirconium and nickel alloys. Due to its low price, it is widely used for mold repair welding. However, it has disadvantages such as large welding heat affected area and large solder joints. Precision mold repair has been gradually replaced by laser welding.

Welding f theta lenses factory China

2. Laser surfacing repair Laser welding is welding using a laser beam focused by a high-power coherent monochromatic photon stream as a heat source. This welding method usually includes continuous power laser welding and pulsed power laser welding. The advantage of laser welding is that it does not need to be carried out in a vacuum, but the disadvantage is that the penetration is not as strong as electron beam welding. Accurate energy control can be carried out during laser welding, so the welding of precision devices can be realized. It can be applied to many metals, especially to solve the welding of some difficult-to-weld metals and dissimilar metals. It has been widely used for mold repair.