CO2 laser failure analysis and inspection

CO2 laser is an integrated structure of light, machine, and electricity, and any one of them will affect the other aspects, so the fault phenomenon is often a complex and complex reaction. The failure of the CO2 laser is studied from the following three aspects.

1) No laser output

This is the fault with the highest frequency of CO2 laser in use. Fault analysis and inspection should be conducted from three aspects.

First check the high-voltage power supply circuit, because the machine's DC high-voltage power supply is up to 24kV. Use the switch knob, indicator light and corresponding voltmeter on the panel to analyze and judge the fault. In the case of power failure, measure whether the high-voltage power supply circuit is open, confirm whether the high-voltage transformer itself is normal, measure and check the thyristor and its trigger circuit responsible for adjusting the output voltage, and use a high-voltage meter with a range greater than 30kV when energized Measure the voltage value output by the DC high-voltage circuit.

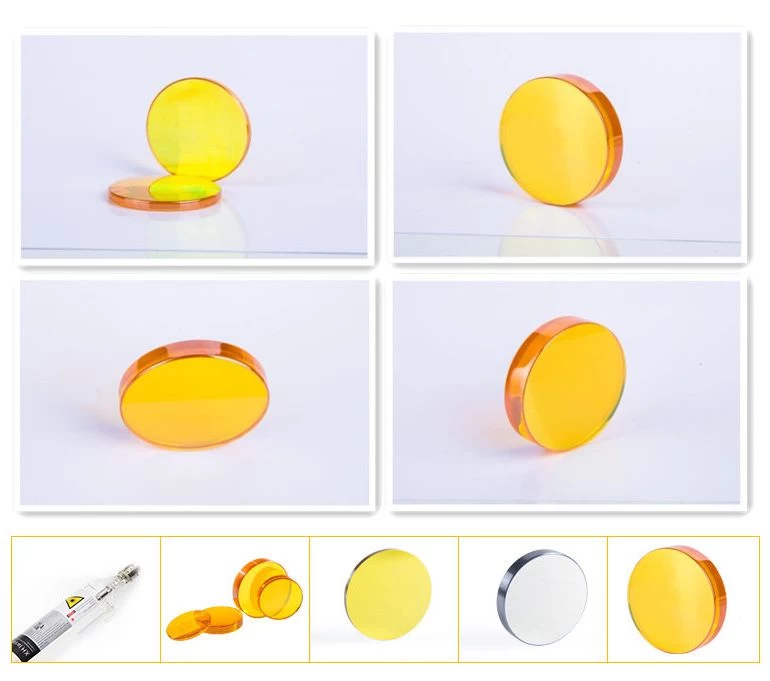

Chinese Most popular Co2 Laser Head With Mirror Mount Manufacturer

Next, check the optical path and carefully observe whether the central axis of the light guide arm mount coincides with the central axis of the CO 2 laser tube (should coincide), and whether the fixing ring of the CO 2 laser tube is loose; whether the flat convex lens on the output side of the laser tube is normal , Whether the output window is clean. Finally, check the laser tube. If the laser tube discharges normally, but there is no laser output, the cavity at both ends of the laser tube may be damaged or the output window may be covered. The laser tube has abnormal discharge and no laser output. The anode or cathode in the laser tube may be damaged, or the working gas in the tube may be contaminated with impurity gas. If there is no discharge or laser output from the laser tube, the cathode may be damaged or aging and cannot emit electrons. The glass at the cathode or anode lead seal bursts or the air at the junction of the two ends of the laser tube leaks, and air enters the laser tube. The laser tube cannot discharge.

Laser focusing lens manufacturer china

2) Weak laser output

The cause of such failures is even more difficult to analyze and check than failures without laser output. It still needs to be carried out from three aspects: high DC power supply circuit, laser light path, and laser tube itself, and more emphasis is placed on the quantification of indicators throughout the process. Check whether the value of the power supply voltage is normal, turn the laser power fine-tuning knob to see whether the value of the milliampere meter can continuously change sensitively. The inspection of the laser tube includes the appearance and structure observation, the correct position of each link of the optical path, and the calculation of the cumulative work of the laser tube. Time (efficiency decreases after laser tube aging and output becomes smaller).

3) Protection circuit failure

The protection circuit fails and the lasers stop working. Overcurrent protection circuit to prevent the laser tube from being damaged due to circuit failure and causing the electrode to be damaged or the electrode wire seal to burst (once burst, the consequences are serious), engineering and technical personnel should take regular preventive maintenance on the protection circuit, Passive maintenance (that is, maintenance after failure) is not desirable.