Advantages and difficulties of laser welding process for power battery

In power battery welding, the welding process technicians will select the appropriate laser and welding process parameters according to the battery material, shape, thickness, tensile force requirements, etc., including welding speed, waveform, peak value, welding head inclination angle, etc. to set a reasonable welding process Parameters to ensure the final welding effect. So, what benefits can laser welding bring to merchants? What difficult problems should be paid attention to during operation?

Advantages of laser welding

1.The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

2.High cooling rate, which can weld fine weld structure and good joint performance.

3.The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

4.No consumables, small size, flexible processing, low operating and maintenance costs.

The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot. Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly increasing work efficiency.

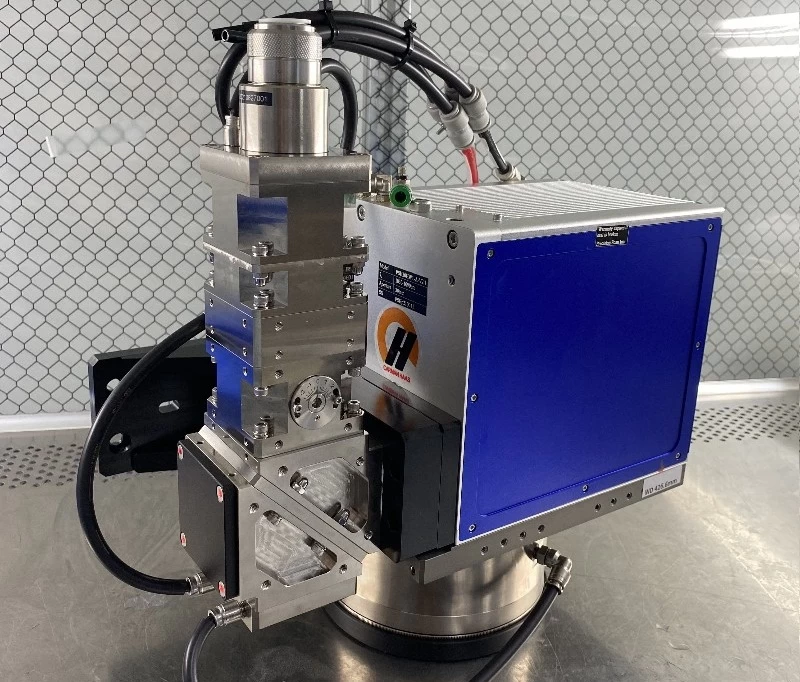

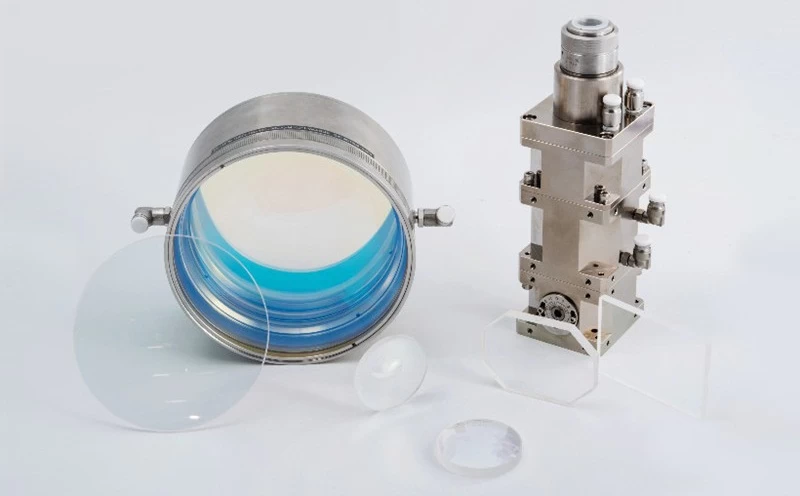

Laser Welding Suppler China CARMAN HAAS Laser Technology (Suzhou) Co,Ltd. supply a Scanner Welding System, it integrates functions such as Laser Source, Scanning Welding head, Beam Control, Visual Positioning, Safety system, Cooling system, Shutter, etc., has a high degree of integration.

It can provide high-strength welding for various material combinations, especially when welding between copper materials and aluminum materials is more effective.

Difficulties of laser welding process

The battery shell made of aluminum alloy material accounts for more than 90% of the entire power battery. The difficulty of welding is that aluminum alloy has extremely high reflectivity to laser and high pore sensitivity during welding. Some problems and defects will inevitably appear during welding. Among them, the most important ones are pores, hot cracks and explosions.

There are two main types of pores in the laser welding process of aluminum alloy: hydrogen pores and pores caused by bubble bursting. Because the cooling rate of laser welding is too fast, the problem of hydrogen gas holes is more serious, and there are more holes caused by the collapse of small holes in laser welding.

Aluminum alloy is a typical eutectic alloy. Hot cracks are prone to occur during welding, including weld crystallization cracks and HAZ liquefaction cracks. Due to the segregation of components in the weld zone, eutectic segregation will occur and grain boundary melting will occur. Liquefaction cracks are formed at the grain boundaries, reducing the performance of welded joints.

There are many factors that cause explosions, such as the cleanliness of the material, the purity of the material itself, and the characteristics of the material itself. The decisive factor is the stability of the laser. Protrusions, pores and internal air bubbles on the shell surface. The main reason is that the fiber core diameter is too small or the laser energy is set too high. The use of appropriate process parameters is the fundamental solution to the problem.

CARMAN HAAS Laser Technology (Suzhou) Co,Ltd. supply a Scanner Welding System. The specially designed control system can meet the needs of customers in different fields. The control system is highly integrated and equipped with a special safety system, making it safer, more convenient and reliable for customers to use. Welcome to contact us Welding F Theta Lenses Factory China to learn more.